Introduction

A constant, reliable flow of water is something many well owners take for granted—until the day the taps run dry or the pressure drops to a trickle. Often, the culprit is a failing submersible water well pump. These hardworking devices, located deep within your well, are designed for years of service, but they don't last forever.

Replacing a submersible water pump is a significant project that requires mechanical skill, the right tools, and a strong emphasis on safety. While many homeowners opt to hire a professional, understanding the process is invaluable. This guide will walk you through diagnosing a pump problem, the tools you'll need, and the step-by-step process of how to replace a submersible water well pump.

Diagnosing a Failing Submersible Pump

Before you invest in a new pump and dedicate a day to this labor-intensive job, ensure the pump is actually the problem. Here are common signs of a failing submersible pump:

· No Water: The most obvious sign. You turn on a faucet and nothing comes out.

· Low Water Pressure: A significant drop in pressure throughout the house could indicate a failing pump.

· Spitting Faucets: Air in the water lines often points to a drop in the water level or a leak in the drop pipe.

· Frequent Pump Cycling: The pump turns on and off rapidly, which could be a bad pressure tank, a waterlogged bladder, or a leak, but can also stress the pump to failure.

· Dirty or Muddy Water: A sudden change in water quality could mean the pump is sucking sediment from a well that’s running dry or that the pump intake is clogged.

· High Electricity Bills: A pump that is struggling to build pressure will run longer, increasing your energy costs.

First, always check your well system’s pressure tank and pressure switch. A faulty pressure switch or a waterlogged bladder in the tank can mimic symptoms of a bad pump. If those components are functioning correctly, the pump is likely the issue.

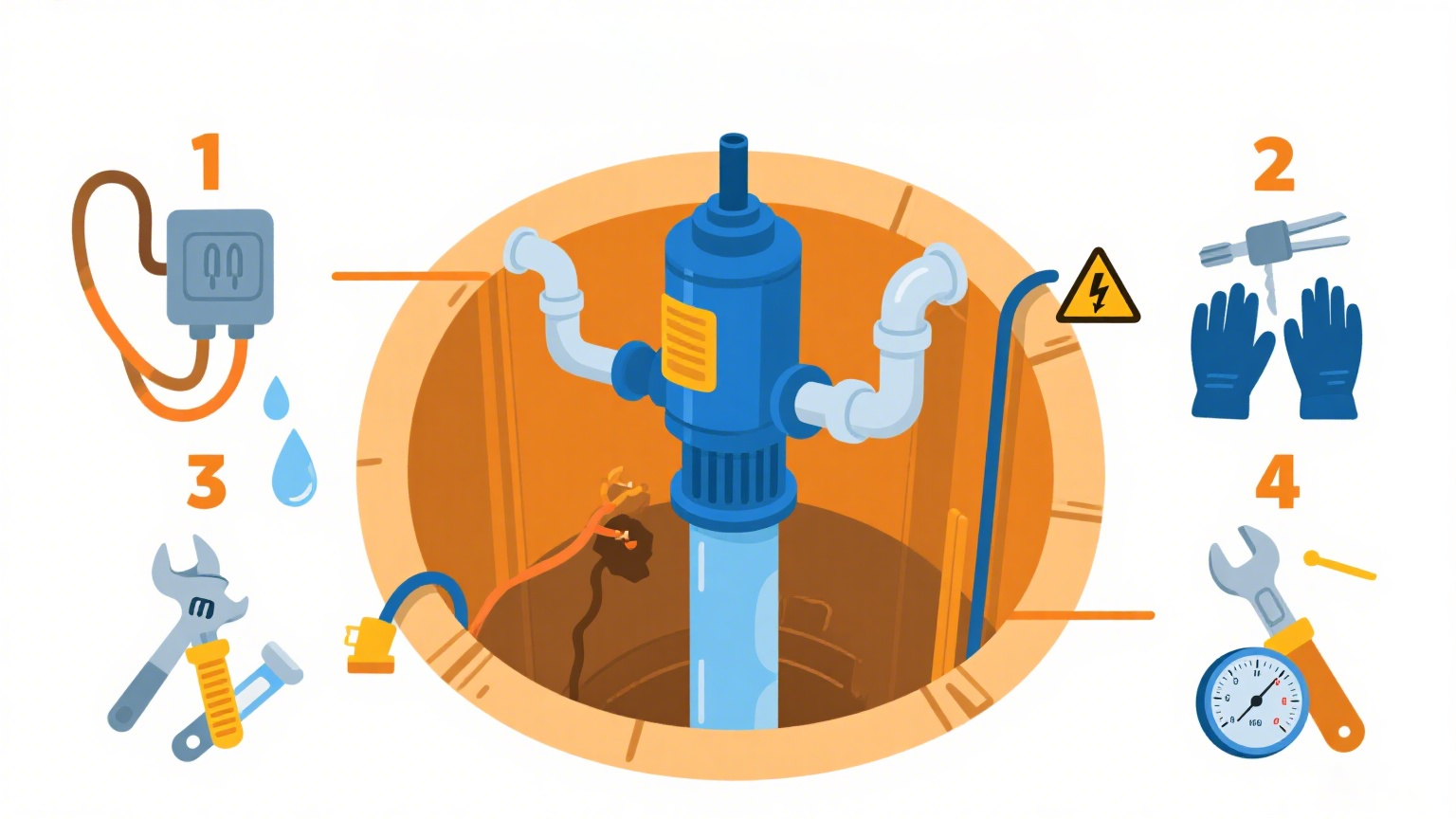

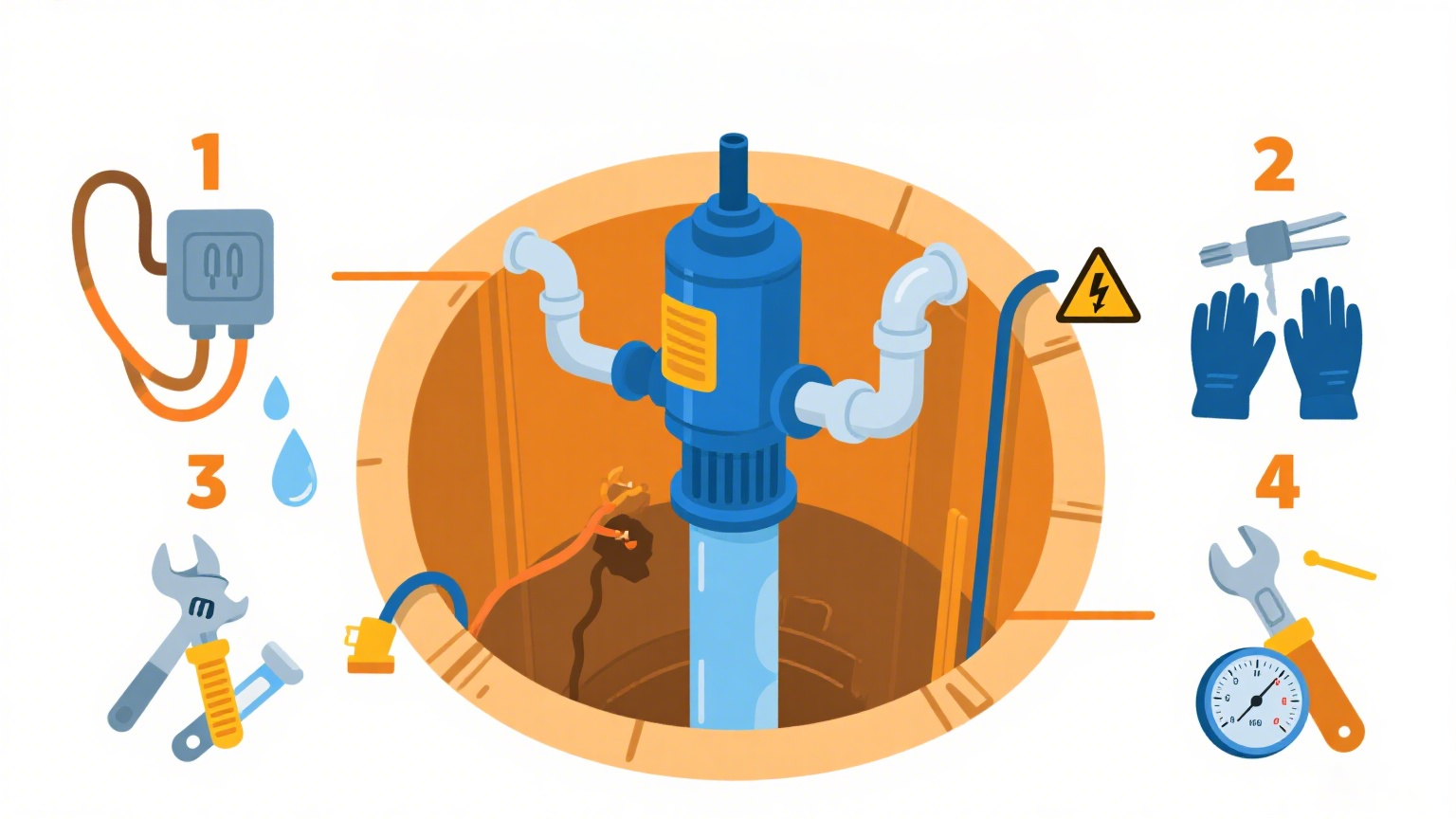

Safety First: Crucial Precautions

This job involves electricity, heavy lifting, and working around a deep well. Do not proceed if you are not confident.

1.DISCONNECT POWER: This is the most critical step. Turn off the circuit breaker that supplies power to the well pump at the main service panel. Use a voltage tester at the well’s pressure switch and control box (if present) to confirm the power is off.

2.DISCHARGE PRESSURE: Shut off the power to the pump and open a faucet to drain the system. This relieves pressure from the pipes and prevents a dangerous surge of water when you disconnect the plumbing.

3.SECURE THE WORKSITE: The well cap and the area around the well casing can be slippery and uneven. Ensure the area is clear and you have stable footing.

4.GET HELP: A submersible pump, especially with hundreds of feet of pipe attached, is extremely heavy. You absolutely need at least one other strong person to assist. Use a proper well-pull tripod or hoist if possible.

5.CALL A PROFESSIONAL IF: The well is very deep (over 200 feet), you lack the proper tools, or you are unsure about any step. Mistakes can be costly and dangerous.

Tools and Materials You’ll Need

· New submersible water well pump (correct HP and GPM rating for your well)

· New drop pipe (e.g., NSF-approved PVC, Polyethylene) Optional but highly recommended

· New wire nuts/waterproof splice kit

· New safety rope (stainless steel or nylon)

· Pipe wrenches (2) or sturdy channel-lock pliers

· Well seal puller or cap removal tools

· Well hoist or tripod (can be rented)

· Torque arrestor and cable guards (if not present)

· Teflon tape or pipe thread sealant

· Electrical tape, voltage tester

· Hose clamps

· A helper (or two!)

Step-by-Step Replacement Guide

Step 1: Remove the Old Pump

After disconnecting power and draining the system, remove the well cap or seal. You’ll see the electrical wires, the pipe, and the safety rope. Disconnect the electrical wires at the splice point, taking a photo first to note the wiring configuration. Carefully unscrew the plumbing connection at the pitless adapter or wellhead. Attach your hoist to the pipe and begin pulling it up, section by section.

As you pull, have your helper guide the pipe and wires, keeping them from kinking or rubbing against the well casing. Unscrew each section of pipe as it emerges and lay it out straight to measure the total depth. Once the pump is out, inspect the old pump, wire, and pipe for damage to help diagnose the failure cause.

Step 2: Prepare the New Pump

While the old pump is out, it’s the perfect time to replace the drop pipe and wire. Using new materials prevents future leaks and electrical issues. Attach the new safety rope to the pump’s built-in rope eyelet. Never use the electrical wires or pipe to support the pump’s weight.

Next, connect the new drop pipe to the pump’s discharge outlet. Use Teflon tape and tighten it securely with a pipe wrench. Slide a torque arrestor onto the pipe (if used) and secure it according to the manufacturer's instructions. Attach the electrical wires to the pump’s leads using a waterproof splice kit, following the color-coding (usually Black/Black, Red/Red, Green/Green). Wrap the connection tightly with waterproof electrical tape.

Step 3: Lower the New Pump into the Well

This is a slow and careful process. Start by feeding the pump carefully into the well casing. Attach cable guards every 100 feet or so to protect the wires from chafing against the well casing. Lower the pump slowly, section by section, connecting new lengths of pipe as you go.

Ensure all pipe connections are tight and straight. Your helper’s job is to carefully feed the wire and rope without letting them tangle or kink. The goal is to get the pump to the correct depth—typically 10-20 feet above the well bottom to avoid sediment.

Step 4: Reconnect at the Wellhead

Once the pump is at the desired depth, you need to connect the drop pipe to the pitless adapter, which allows water to flow horizontally to your pressure tank. This can be the trickiest part, requiring you to guide the pipe onto the adapter’s O-ring seal. Follow the manufacturer’s instructions carefully. Once connected, pull up slightly to ensure it’s locked in place.

Secure the safety rope to the well cap anchor point. Bring the electrical wires up through the well cap and make the final splice connection in the junction box, again ensuring it is waterproof.

Step 5: Prime and Test the System

Before replacing the well cap, double-check all connections. Once secure, you can restore power at the circuit breaker. The pump should kick on immediately to begin building pressure in the system. It may take several minutes to prime and push water to the tank.

Open a faucet to bleed air from the lines. Listen for unusual noises and monitor the pressure gauge on the tank. It should build to the cut-off pressure (typically 40/60 or 30/50 psi) and then shut off. Check for leaks at the wellhead and around the pressure tank.

When to Call a Professional Well Contractor

Pulling and replacing a submersible water pump is a major undertaking. You should strongly consider hiring a licensed well contractor if:

· Your well is deeper than 200 feet.

· The pump is stuck in the well.

· You are not comfortable working with high-voltage electricity.

· You don't have access to a hoist or the necessary tools.

· The problem is not clearly the pump (it could be a well depth issue).

While DIY can save on labor costs, a professional ensures the job is done safely and correctly, protecting your most vital resource: clean, accessible water.

Submersible Water Well Pump

Submersible Well Pump

Submersible Water Pump

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Afrikaans

Oʻzbekcha

Azərbaycan dili

Беларуская мова

Български

ქართული

Hausa

Кыргызча

Македонски

Soomaali

Тоҷикӣ

Türkmençe